TMS 402 provides comprehensive standards for masonry structures, ensuring safety, durability, and compliance with modern engineering practices. It serves as a vital resource for engineers and contractors.

Overview of TMS 402

TMS 402 is a comprehensive standard that provides detailed requirements for the design, construction, and testing of masonry structures. It serves as a key reference for engineers, architects, and contractors, ensuring compliance with modern engineering practices. The standard covers various aspects, including material specifications, load-bearing capacities, and seismic design provisions. TMS 402 is developed collaboratively by The Masonry Society (TMS), American Concrete Institute (ACI), and American Society of Civil Engineers (ASCE), making it a widely recognized and authoritative document. It is applicable to both new constructions and the evaluation of existing masonry structures. The standard emphasizes safety, durability, and cost-effectiveness, making it indispensable for professionals involved in masonry projects. Its guidelines are regularly updated to reflect advancements in materials and construction techniques, ensuring it remains relevant in the evolving field of structural engineering.

Importance of TMS 402 in Masonry Structures

TMS 402 is critical for ensuring the safety, durability, and performance of masonry structures. It provides standardized design, construction, and testing guidelines, promoting consistency and reliability in the industry. By adhering to TMS 402, engineers and contractors can ensure compliance with building codes and industry standards, ultimately protecting public safety. The standard addresses load-bearing capabilities, material specifications, and seismic resistance, making it indispensable for modern masonry projects. Its guidelines help mitigate risks associated with structural failures and ensure that masonry structures withstand various environmental and operational stresses. TMS 402 also supports innovation by incorporating advancements in materials and techniques, making it a foundational document for the masonry profession.

Key Sections of TMS 402

TMS 402 outlines essential sections for masonry structures, including design requirements, material specifications, construction guidelines, and testing procedures, ensuring comprehensive industry standards.

Design Requirements for Masonry Structures

TMS 402 outlines specific design requirements for masonry structures, ensuring they can withstand various loads and stresses. It covers load-bearing walls, beams, and columns, providing detailed calculations for structural integrity. The standard emphasizes proper material selection and reinforcement details to maximize durability. Designers must adhere to allowable stress design (ASD) and strength design methods, as outlined in the code. Additionally, it addresses seismic considerations, ensuring masonry structures can resist earthquake forces. Compliance with these requirements is crucial for safety and long-term performance. The document also references related standards like ACI 530 and ASCE 5 for comprehensive design guidance.

By following TMS 402, engineers can ensure masonry structures meet modern engineering and safety standards, reducing risks and enhancing reliability.

Material Specifications and Standards

TMS 402 provides detailed material specifications for masonry construction, ensuring compliance with industry standards. It covers requirements for clay brick, concrete block, grout, and mortar, as well as reinforcement materials; The standard specifies testing procedures for material strength, durability, and compatibility. Proper mix designs for grout and mortar are emphasized to ensure structural integrity. Compliance with ASTM standards for masonry materials is mandated, and updates in the 2022 edition address sustainability and performance. These specifications ensure that materials meet quality and safety criteria, crucial for reliable masonry structures. Adherence to these standards minimizes risks and enhances long-term durability.

By adhering to TMS 402, contractors and engineers can ensure materials are suitable for their intended applications, meeting both functional and safety demands.

Construction and Testing Guidelines

TMS 402 outlines detailed construction and testing guidelines to ensure masonry structures meet rigorous standards. It specifies requirements for mortar, grout, and reinforcement placement, as well as inspection protocols. The standard emphasizes proper installation techniques to maintain structural integrity and durability. Testing procedures include compressive strength tests for masonry assemblies and bond strength evaluations between masonry units and mortar. Quality control measures are highlighted to verify compliance with design specifications. Regular inspections are mandated to identify and address defects early in the construction process. These guidelines ensure that masonry construction aligns with safety, performance, and durability expectations, while also addressing potential challenges in implementation.

Historical Context and Development

TMS 402 evolved from collaborative efforts between TMS, ACI, and ASCE to standardize masonry design and construction. It reflects decades of advancements in materials and engineering practices.

Evolution of Masonry Codes and Standards

Masonry codes and standards have evolved significantly, reflecting advancements in materials and engineering. TMS 402-11/ACI 530-11/ASCE 5-11 and TMS 602-11/ACI 530.1-11/ASCE 6-11 represent the culmination of collaborative efforts to unify design and construction practices. These documents incorporate lessons from historical structures, addressing durability, safety, and seismic resilience. Earlier versions laid the groundwork, while modern updates integrate innovative materials and techniques. The evolution ensures that masonry remains a viable, sustainable option for building design, aligning with current engineering knowledge and regulatory requirements. This progression underscores the commitment to improving masonry’s role in contemporary construction, providing clear guidelines for engineers and contractors to deliver structurally sound and aesthetically pleasing buildings.

Previous Versions of TMS 402

Previous versions of TMS 402, such as TMS 402-11, established foundational guidelines for masonry design and construction. These earlier editions laid the groundwork for modern standards, addressing material specifications and construction practices. They reflected the engineering knowledge of their time, incorporating feedback from industry professionals. Over the years, updates have enhanced safety, durability, and compliance with building codes. Earlier versions also highlighted the importance of collaboration between TMS, ACI, and ASCE, ensuring a unified approach to masonry standards. These updates have been instrumental in shaping current practices, providing a historical context for the development of TMS 402. Each version built upon the last, refining requirements to meet evolving demands in construction and engineering. This iterative process has solidified TMS 402 as a cornerstone of masonry standards.

Collaboration Between TMS, ACI, and ASCE

The collaboration between TMS, ACI, and ASCE has been instrumental in developing comprehensive standards for masonry structures. TMS 402, also known as ACI 530 and ASCE 5, reflects a unified approach to masonry design and construction. This joint effort ensures that the standards are well-rounded, practical, and aligned with industry needs. By combining the expertise of these organizations, TMS 402 provides a cohesive framework for engineers, architects, and contractors. The collaboration also facilitates regular updates, incorporating the latest research and feedback from professionals. This teamwork has been crucial in addressing evolving challenges in masonry construction, ensuring that the standards remain relevant and effective. The partnership underscores the importance of a collaborative approach in advancing engineering and construction practices. As a result, TMS 402 has become a trusted resource for designing safe and durable masonry structures.

Technical Specifications in TMS 402

TMS 402 outlines detailed technical specifications for masonry design, including load-bearing walls, reinforced masonry, and seismic requirements, ensuring compliance with modern engineering standards and practices.

Load-Bearing Masonry Design

TMS 402 provides detailed specifications for load-bearing masonry design, ensuring structural integrity and safety. It covers material strength, stress calculations, and construction methods, essential for reliable masonry structures in buildings.

Reinforced Masonry Details

TMS 402 outlines detailed specifications for reinforced masonry, focusing on the integration of steel reinforcement within masonry elements. It provides guidelines for material selection, reinforcement placement, and design calculations. The standard emphasizes proper detailing to ensure structural stability and durability. Key aspects include the use of grout and mortar, reinforcement spacing, and the capacity of masonry assemblies under various loads. Compliance with these details ensures adherence to safety and performance standards, critical for modern masonry construction. Engineers and contractors rely on TMS 402 to design reinforced masonry systems that meet building codes and withstand environmental and seismic challenges.

Seismic Design Provisions

TMS 402 includes specific seismic design provisions to enhance the resilience of masonry structures in earthquake-prone regions. These provisions detail requirements for reinforced masonry elements, such as walls, beams, and columns, to resist seismic forces effectively. The standard emphasizes proper detailing, including reinforcement ratios, spacing, and anchorage, to ensure ductility and energy dissipation. Designers must consider seismic hazard levels, soil types, and building occupancy to determine design forces. The provisions also address the integration of masonry with other structural systems, ensuring a cohesive and resilient design. By adhering to these guidelines, engineers can create masonry structures that meet modern seismic safety standards, reducing the risk of damage and ensuring occupant safety during earthquakes.

Compliance and Safety

TMS 402 ensures masonry structures meet building codes and safety standards, emphasizing proper materials, construction practices, and inspections to guarantee reliability and occupant safety.

Building Code Requirements

TMS 402 outlines specific building code requirements for masonry structures, ensuring compliance with safety and design standards. It collaborates with ACI and ASCE to provide detailed guidelines for load-bearing and reinforced masonry. The standard covers material specifications, construction practices, and testing protocols to ensure structural integrity. Key aspects include design loads, reinforcement details, and seismic provisions, all aligned with current engineering practices. Compliance with TMS 402 is essential for meeting local and international building codes, ensuring the reliability and safety of masonry constructions. By adhering to these requirements, engineers and contractors can deliver durable and hazard-resistant structures, meeting the needs of modern construction projects effectively.

Safety Factors in Masonry Construction

TMS 402 emphasizes critical safety factors in masonry construction, ensuring structures are resilient and secure. It addresses material strength, load capacities, and environmental impacts, providing guidelines to minimize risks. The standard mandates regular inspections and quality control measures to uphold safety standards. By specifying safety factors, TMS 402 helps prevent structural failures and ensures the well-being of occupants. Compliance with these guidelines is paramount for achieving safe and durable masonry constructions, meeting both regulatory requirements and industry best practices. This focus on safety underscores the importance of adhering to TMS 402 in all masonry projects, ensuring reliable and hazard-resistant structures.

Inspection and Quality Control

TMS 402 outlines rigorous inspection and quality control processes to ensure masonry structures meet specified standards. Regular on-site inspections are mandated to verify materials, workmanship, and compliance with design specifications. Quality control measures include testing of masonry materials, such as mortar and brick strength, to ensure they meet required standards. Documentation of all inspections and test results is required to maintain transparency and accountability. These protocols help identify and address potential issues early, preventing costly repairs and ensuring structural integrity. By emphasizing inspection and quality control, TMS 402 promotes consistency, reliability, and adherence to best practices in masonry construction, ultimately safeguarding the longevity and safety of the structure.

Application in Real-World Projects

TMS 402 guidelines are widely applied in constructing masonry structures, ensuring safety and compliance. Real-world projects benefit from its practical design and construction standards, enhancing durability and performance.

Case Studies of Masonry Structures

Case studies of masonry structures highlight the practical application of TMS 402 standards in real-world scenarios. These studies demonstrate how the code ensures safety, durability, and compliance in various projects. By analyzing successful implementations, engineers and contractors gain insights into designing and constructing masonry systems that meet modern engineering challenges. For instance, historic buildings renovated using TMS 402 guidelines showcase the balance between preserving heritage and enhancing structural integrity. Additionally, new constructions utilizing reinforced masonry detail examples from the standard illustrate improved seismic resistance and load-bearing capacity. These case studies also reveal common challenges, such as material selection and construction delays, offering lessons for future projects. They serve as valuable resources for professionals aiming to optimize masonry design and construction practices while adhering to TMS 402 requirements.

Challenges in Implementing TMS 402

Implementing TMS 402 presents several challenges, including material compatibility issues and complex design requirements. Engineers often face difficulties in interpreting load-bearing masonry specifications and ensuring compliance with seismic provisions. Additionally, the standard’s emphasis on precise construction tolerances can lead to delays and increased costs. Another challenge is the need for specialized training for contractors to understand reinforced masonry details and testing procedures. Furthermore, updates to the standard require continuous adaptation, which can be time-consuming. Despite these obstacles, adherence to TMS 402 ensures structural integrity and safety, making the challenges worthwhile for professionals committed to quality masonry construction. Collaboration between engineers and contractors is essential to overcome these hurdles effectively.

Best Practices for Engineers and Contractors

Engineers and contractors should adhere to TMS 402 guidelines by conducting thorough material testing and following specified construction protocols. Regular inspections ensure compliance with safety standards and structural integrity. Collaboration between teams enhances understanding of design requirements, while continuous training keeps professionals updated on the latest standards. Proper documentation of all processes facilitates quality control and simplifies compliance verification. By prioritizing these practices, professionals can deliver durable and safe masonry structures that meet TMS 402 specifications, ensuring long-term performance and reliability in various applications.

TMS 402 stands as a cornerstone for masonry standards, ensuring safety and durability. Its evolving guidelines continue to shape modern construction, fostering innovation and excellence in the industry.

Future of Masonry Standards

The future of masonry standards, as outlined in TMS 402, is poised for significant advancements. Sustainability will play a central role, with a focus on eco-friendly materials and energy-efficient designs. Innovations in material science, such as advanced brick and mortar compositions, are expected to enhance durability and performance. Digital tools like Building Information Modeling (BIM) will likely become integral to masonry design and construction processes. Additionally, there will be a stronger emphasis on seismic resilience and adaptability to climate change. Global collaboration among engineers, architects, and contractors will drive the development of universal standards, ensuring consistency and excellence worldwide. These evolutions will not only maintain but elevate the integrity and reliability of masonry structures in the years to come.

Final Thoughts on TMS 402

TMS 402 stands as a cornerstone for modern masonry design and construction, offering a detailed framework that ensures structural integrity and safety. Its comprehensive guidelines have become essential for professionals seeking compliance with industry standards. The document’s emphasis on material specifications, construction practices, and testing protocols underscores its commitment to quality and innovation. As the construction industry evolves, TMS 402’s adaptability to new technologies and environmental challenges will remain vital. Its role in fostering collaboration between engineers, contractors, and regulators is unparalleled. Ultimately, TMS 402 not only sets the standard for masonry but also shapes the future of the built environment, ensuring that structures are resilient, sustainable, and safe for generations to come.

the good and beautiful bible study pdf

the good and beautiful bible study pdf  memorial day word search pdf

memorial day word search pdf  recovering from emotionally immature parents pdf

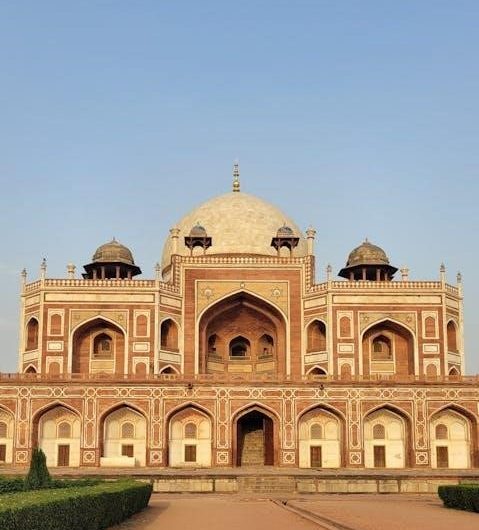

recovering from emotionally immature parents pdf  humayun ahmed pdf

humayun ahmed pdf  c.s. lewis mere christianity pdf

c.s. lewis mere christianity pdf  pathfinder character sheet pdf fillable

pathfinder character sheet pdf fillable  magic bullet user manual

magic bullet user manual  kctv guide

kctv guide  sample shipper’s letter of instruction

sample shipper’s letter of instruction